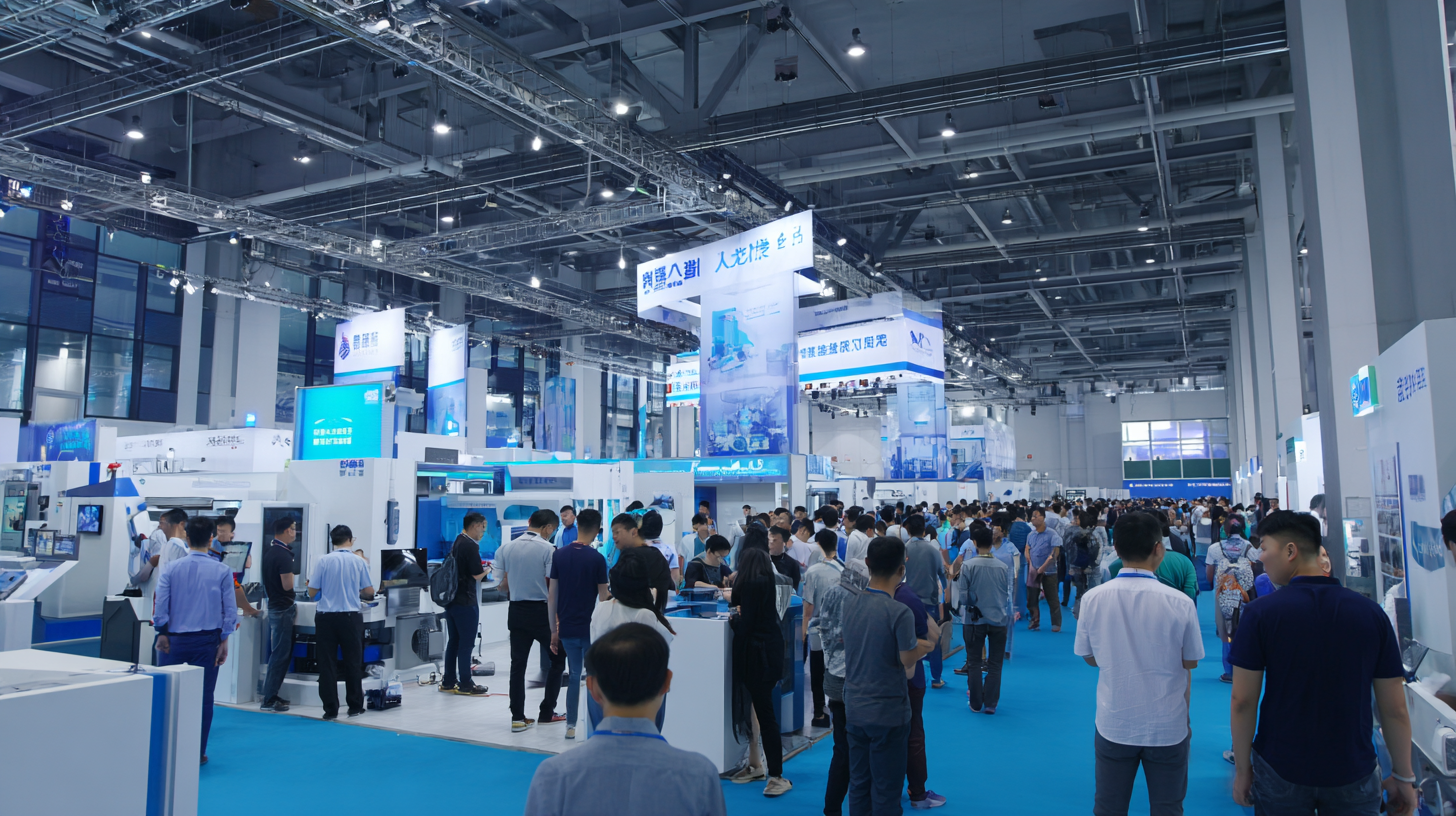

Exploring Thermoplastic Rubber Innovations at 2025 China Import and Export Fair

The upcoming 2025 China Import and Export Fair, recognized as the 138th Canton Fair, promises to be a significant event for industries worldwide, particularly in the realm of innovative materials. Among the various advancements poised to capture attention is the spotlight on Thermoplastic Rubber (TPR) innovations. As a versatile material combining the properties of rubber and thermoplastics, TPR offers a unique blend of flexibility, durability, and recyclability, making it ideal for a wide range of applications across automotive, consumer goods, and construction sectors. This year's fair will not only showcase cutting-edge products but also facilitate dialogues on the latest technological breakthroughs and sustainability practices surrounding Thermoplastic Rubber. As stakeholders from around the globe convene, they will explore the transformative potential of TPR in meeting modern market demands and consumer preferences, positioning it as a key player in the future of material science.

Innovative Applications of Thermoplastic Rubber in Various Industries

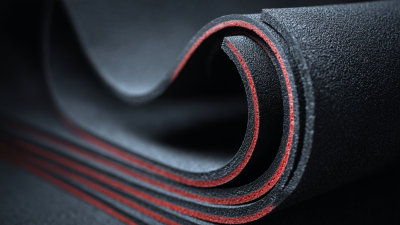

The 2025 China Import and Export Fair is set to showcase groundbreaking innovations in thermoplastic rubber (TPR) that are transforming various industries. This versatile material, known for its elasticity and durability, has found a multitude of applications ranging from automotive components to medical devices. In automotive manufacturing, TPR is increasingly used for sealing systems and weatherstrips, enhancing energy efficiency and vehicle longevity. Meanwhile, in the medical field, its biocompatibility makes it ideal for solutions that require both flexibility and hygiene.

Tips: When exploring TPR solutions, consider the specific demands of your industry. For automotive applications, focus on the material's performance in extreme temperatures and resistance to wear. In medical settings, prioritize biocompatibility and ease of sterilization to ensure patient safety.

As industries continue to innovate, the potential for thermoplastic rubber expands. The construction sector embraces TPR in flooring and protective coatings, thanks to its resistance to chemicals and easy maintainability. Additionally, the consumer goods market benefits from TPR's lightweight yet strong properties, making it a preferred choice for a variety of products. Attendees at the fair can expect inspiration and insights into how TPR innovations can drive efficiency and sustainability in their respective fields.

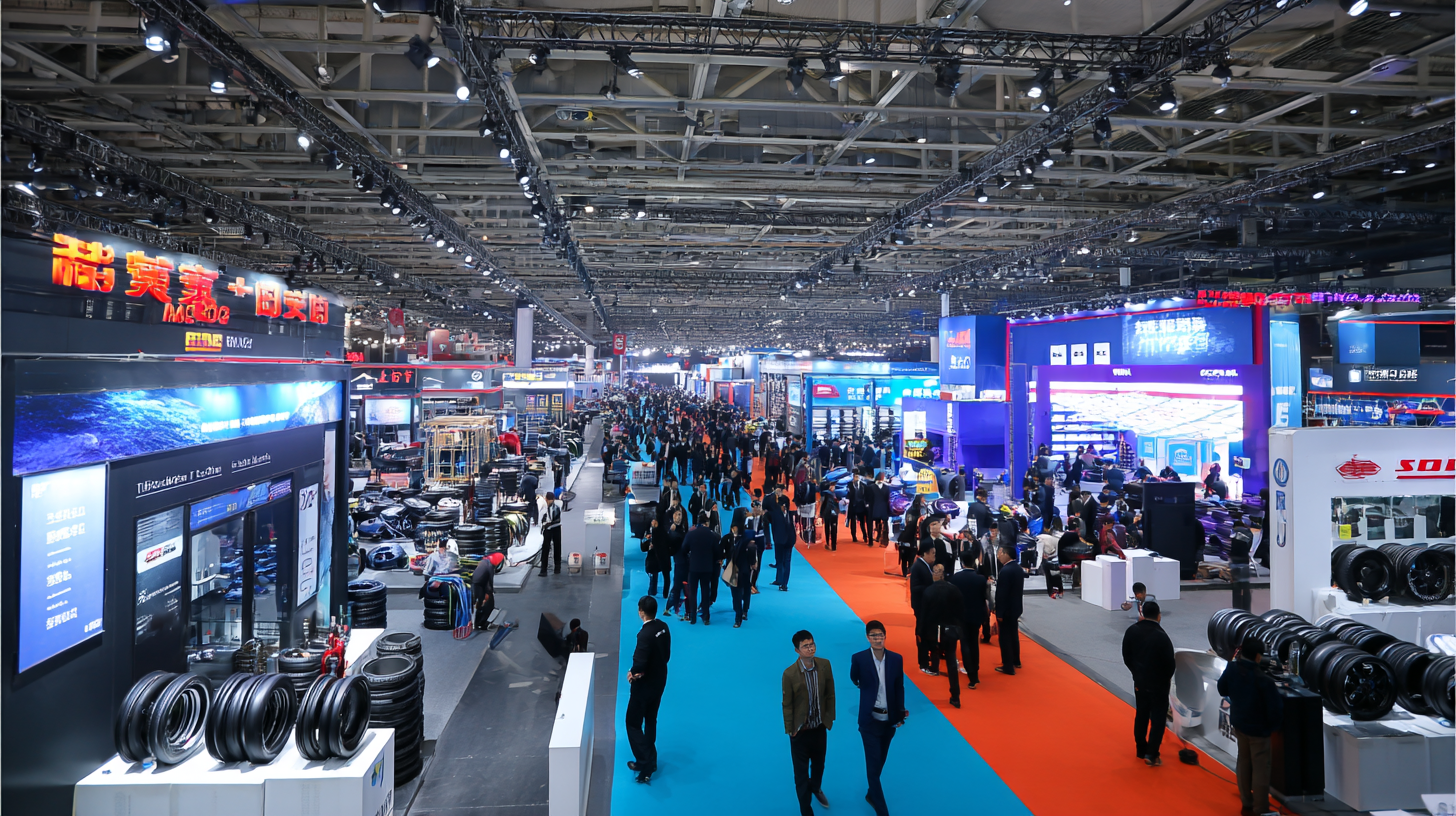

Key Players and Their Latest Developments in Thermoplastic Rubber Technology

The 2025 China Import and Export Fair showcases a significant shift in the thermoplastic rubber industry, featuring key players unveiling their latest advancements in technology. Notably, market analysts from Grand View Research forecast that the global thermoplastic elastomers market will reach approximately $28.5 billion by 2027, driven by the material's versatility and recyclability. Major industry leaders, such as Kraton Corporation and Lanxess, are focusing on bio-based thermoplastic rubbers, responding to growing environmental concerns and consumer demands for sustainable materials.

Tips: When exploring thermoplastic rubber innovations, consider the sustainability of the materials and their applications in various industries. Understanding the unique properties of various thermoplastic elastomers can provide insight into their potential use in automotive, medical, and consumer goods sectors.

Additionally, in light of recent developments, companies are investing heavily in R&D to enhance the performance characteristics of thermoplastic rubbers. For instance, studies reveal that high-performance thermoplastic elastomers can significantly reduce vehicle weight while improving fuel efficiency. Organizations looking to adopt these innovations should stay abreast of technological advancements and regulatory changes impacting the materials industry.

Sustainable Practices in the Production of Thermoplastic Rubber

The 2025 China Import and Export Fair is set to highlight significant advancements in thermoplastic rubber (TPR) technology, particularly through a lens of sustainability. As the global demand for eco-friendly materials surges, the TPR industry is evolving to incorporate sustainable practices in its production processes. According to a report by Grand View Research, the global thermoplastic elastomers market is projected to reach approximately $25 billion by 2025, with a substantial focus on eco-friendly alternatives and production methods. This shift not only aligns with international environmental standards but also caters to consumers increasingly interested in sustainable products.

Companies are leveraging innovative recycling techniques to create TPR from post-consumer waste, thus minimizing their carbon footprint. The use of bio-based materials in TPR formulations has also gained traction. For instance, the recent study published in the Journal of Cleaner Production indicates that integrating renewable resources could reduce greenhouse gas emissions by up to 30% compared to traditional TPR production methods. As manufacturers prepare for the upcoming fair, showcasing these sustainable practices will not only enhance their competitiveness but also strengthen their commitment to an eco-conscious future in the rubber industry.

Future Trends in Thermoplastic Rubber Innovations Post-2025

As the thermoplastic elastomers (TPE) market continues to evolve, significant innovations are anticipated beyond 2025. The market is projected to grow from USD 30.83 billion in 2025 to USD 38.94 billion by 2030, reflecting a commendable compound annual growth rate (CAGR) of 4.8%. This growth underscores increasing demand for versatile materials that combine the properties of rubber and plastics, facilitating advancements in various sectors, including automotive, consumer goods, and healthcare.

Emerging innovations in thermoplastic rubber are expected to be driven by advancements in generative AI, enhancing user experiences in applications like industrial products and consumer-facing technologies. Reports indicate that the industrial rubber products market is set to expand from USD 129.0 billion in 2025 to an impressive USD 243.8 billion by 2035, with a growth rate of 6%. These figures suggest a robust integration of smart solutions and materials that cater to dynamic market needs, setting the stage for groundbreaking applications and products in the years to come.

Exploring Thermoplastic Rubber Innovations at 2025 China Import and Export Fair - Future Trends in Thermoplastic Rubber Innovations Post-2025

| Innovation Type | Description | Potential Applications | Sustainability Impact | Projected Growth (2025-2030) |

|---|---|---|---|---|

| Bio-based TPR | Development of thermoplastic rubber from renewable resources. | Medical devices, consumer goods, automotive applications. | Reduced carbon footprint, biodegradable options. | 15% annually |

| Recycling Innovations | Enhanced techniques for recycling old TPR products. | Construction materials, industrial applications. | Minimized waste and resource recovery. | 10% annually |

| Smart TPR | Integration of sensors and technology within TPR materials. | Wearable technology, smart packaging. | Energy-saving capabilities, enhanced user interaction. | 20% annually |

| Nano-enhanced TPR | Utilization of nanomaterials to improve properties of TPR. | Aerospace components, high-performance footwear. | Higher durability and longevity reduces waste. | 18% annually |

Spotlight on Collaborative Efforts in Thermoplastic Rubber Research and Development

The collaboration in thermoplastic rubber research and development highlights the innovative strides being made in this dynamic field. Recent accolades, such as the ACS Rubber Division's 2024 Science and Technology Awards, underscore the importance of recognizing individual contributions to advancing material science. Innovators like Andrew Chapman and Namita Choudhury are paving the way for enhanced properties and applications of thermoplastic rubber, essential for various industries, including automotive and consumer goods.

Furthermore, the anticipated growth of the styrene isoprene styrene (SIS) market, projected to reach USD 2.76 billion by 2033, emphasizes the increasing demand for these materials. Initiatives such as the recent $9.5 million research funding opportunity from the U.S. National Science Foundation, in partnership with industry leaders, signify a robust interest in sustainable polymers. Such collaborative efforts not only foster innovation but also promote environmentally conscious practices within the industry, setting a foundation for future advancements in thermoplastic rubber technologies.

Innovations in Thermoplastic Rubber - 2025 Insights

This chart highlights the advancements in thermoplastic rubber innovations based on research and development efforts, showcasing the percentage increase of key research areas over the years 2020 to 2025.

Related Posts

-

7 Essential Benefits of Choosing Thermoplastic Rubber for Your Next Project

-

Top 10 Thermoplastic Rubber Manufacturers from China at the 137th Canton Fair

-

Advantages of Utilizing Rubber Processing Techniques for Global Trade

-

Top Strategies for Sourcing the Best Thermoplastic Rubber to Maximize Your Supply Chain Efficiency

-

China's Resilience in Manufacturing Best Ultrasonic Welding Rubber Amidst US China Tariff Challenges

-

Exploring Innovative Alternatives to Polyisoprene Rubber in Modern Manufacturing