Why Nitrile Butadiene Rubber is the Preferred Choice for Industrial Applications

Nitrile Butadiene Rubber (NBR) has emerged as a vital material in various industrial applications due to its exceptional resistance to oils, fuels, and chemicals. According to a report by MarketsandMarkets, the global nitrile rubber market is projected to reach $4.7 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.7% from 2020. This significant growth underscores the increasing demand for NBR in manufacturing sectors such as automotive, aerospace, and oil and gas, where material performance directly impacts safety and efficiency.

The outstanding properties of Nitrile Butadiene Rubber, particularly its durability and flexibility in extreme temperatures, make it the preferred choice for seals, gaskets, and hoses. A study conducted by Grand View Research indicates that the automotive sector alone accounted for over 31% of NBR consumption in 2019, emphasizing its crucial role in producing reliable components that withstand harsh operational environments. As industries continue to prioritize resilience and performance, the adoption of NBR is expected to rise, solidifying its position as a cornerstone material in today's industrial landscape.

Properties of Nitrile Butadiene Rubber and Its Industrial Benefits

Nitrile Butadiene Rubber (NBR) has become a dominant material in various industrial applications due to its exceptional properties. One of the key advantages of NBR is its excellent resistance to oil and fuel, making it an ideal choice for the automotive, aerospace, and oil and gas industries. According to a report by MarketsandMarkets, the global NBR market size was valued at approximately USD 1.1 billion in 2020 and is projected to reach USD 1.6 billion by 2025, growing at a CAGR of 8.5% during the forecast period. This growth is largely driven by the increasing demand for durable sealing applications and components that can withstand harsh conditions.

In addition to oil resistance, NBR exhibits remarkable wear and abrasion resistance, which is vital for heavy machinery and equipment exposed to rigorous conditions. The tensile strength of NBR can peak at around 30 MPa, making it highly durable. Moreover, NBR maintains its flexibility and strength across a wide temperature range, typically from -40°C to 120°C. This ability to perform under extreme conditions further solidifies its standing as the preferred elastomer in industries requiring reliable performance. Furthermore, NBR’s adhesion properties allow for effective bonding with other materials in composite applications, enhancing its versatility across various sectors, including manufacturing and construction.

Common Industrial Applications of Nitrile Butadiene Rubber

Nitrile Butadiene Rubber (NBR) has gained significant traction in various industrial applications due to its superior properties such as excellent resistance to oils, heat, and mechanical wear. One of the most common uses of NBR is in the manufacturing of seals and gaskets, where its ability to withstand extreme temperatures and provide airtight seals is crucial. Industries like automotive and aerospace heavily rely on NBR components to enhance durability and dependability in harsh operating environments.

Another prominent application of NBR is in the production of hoses and belts. The flexibility and resilience of this synthetic rubber make it an ideal choice for applications that require both high tensile strength and resistance to abrasion. These qualities ensure reliable performance in diverse settings, from construction sites to manufacturing plants.

Tips: When choosing NBR for your industrial applications, consider the specific operating conditions such as temperature extremes and exposure to chemicals. Additionally, ensure proper storage and handling of NBR products to maintain their properties over time. Always consult with a materials specialist to select the right grade of NBR that will best meet your operational requirements.

Why Nitrile Butadiene Rubber is the Preferred Choice for Industrial Applications

| Application | Key Properties | Temperature Resistance | Common Uses |

|---|---|---|---|

| Automotive Seals | Oil resistance, durability | -40°C to 120°C | Gaskets, O-rings |

| Aerospace Components | Flexibility, low compression set | -50°C to 150°C | Fuel hoses, seals |

| Industrial Hoses | Chemical resistance, longevity | -30°C to 100°C | Transfer hoses in machinery |

| Electrical Insulation | Dielectric strength, thermal stability | -40°C to 125°C | Wire insulation, connectors |

| Medical Devices | Biocompatibility, flexibility | -20°C to 100°C | Surgical gloves, tubing |

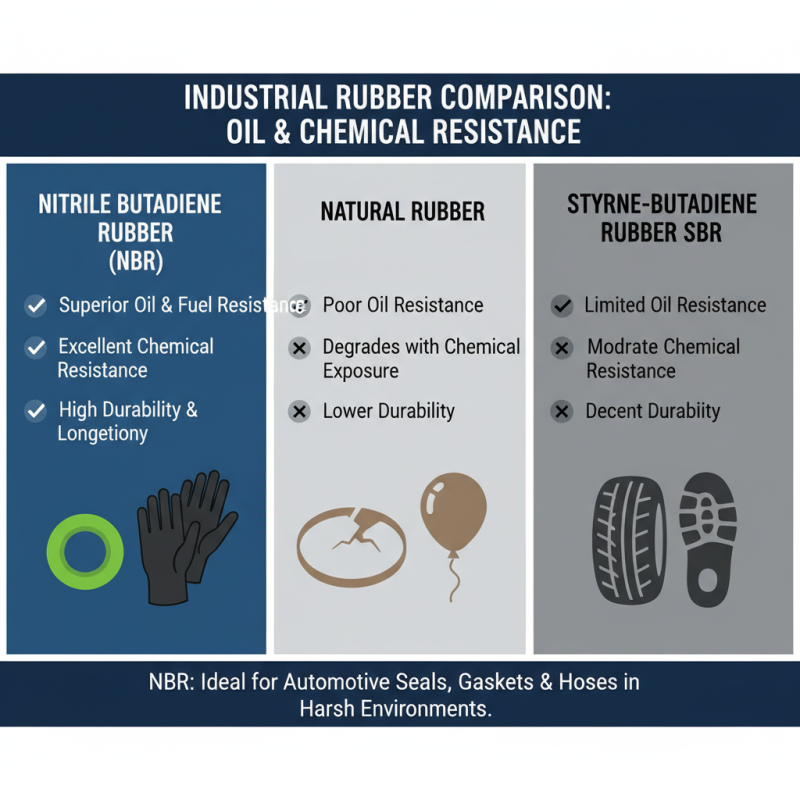

Comparison with Other Rubber Types in Industrial Use

Nitrile Butadiene Rubber (NBR) stands out in industrial applications due to its excellent resistance to oils, fuels, and other chemicals, making it highly suitable for environments where these substances are prevalent. When compared to other rubber types, such as natural rubber, which is more susceptible to degradation under oil exposure, NBR demonstrates superior durability and longevity. Additionally, synthetic rubbers like SBR (Styrene-Butadiene Rubber) may offer decent performance, but they lack the oil resistance that NBR provides, limiting their use in applications such as automotive seals and gaskets.

Another critical factor in favor of NBR is its resistance to wear and tear, which is essential in high-friction applications. While EPDM (Ethylene Propylene Diene Monomer) rubber is renowned for its weather resistance, it does not perform as well in oil-related applications. NBR, with its capacity to maintain integrity under stress and exposure, is often the preferred choice in manufacturing hoses, belts, and other components that require both flexibility and toughness. Thus, the combination of chemical resistance, durability, and performance under pressure positions Nitrile Butadiene Rubber as the superior choice in various industrial contexts.

Factors Influencing the Selection of Nitrile Butadiene Rubber

Nitrile butadiene rubber (NBR) is favored in industrial applications due to several key factors that influence its selection. One of the primary considerations is its excellent resistance to oils and fuels, making it ideal for industries such as automotive and aerospace. This characteristic not only extends the lifespan of components but also reduces maintenance costs, thereby enhancing operational efficiency. Additionally, NBR exhibits strong abrasion resistance, which is crucial in environments where wear and tear can significantly affect performance.

Another important factor influencing the choice of nitrile butadiene rubber is its flexibility in formulation. Manufacturers can tailor NBR blends to meet specific requirements, such as temperature tolerance and hardiness against various chemicals. This versatility allows for its use in a wide range of applications, from seals and gaskets to protective gear and conveyor belts. Furthermore, NBR performs well in a broad temperature range, providing stability in various operational conditions. This adaptability and resilience make NBR an essential material in many industrial processes, ultimately contributing to enhanced productivity and safety.

Why Nitrile Butadiene Rubber is the Preferred Choice for Industrial Applications

Sustainability and Environmental Considerations in Nitrile Use

Nitrile Butadiene Rubber (NBR) is increasingly recognized for its superior environmental sustainability compared to other synthetic rubbers. As industries strive to meet sustainability goals outlined in various global agreements, NBR shines as it is produced with a focus on reducing environmental impact. According to a report by the market research firm Grand View Research, the global demand for nitrile rubber is expected to surpass 1.5 million metric tons by 2027, driven in part by its favorable life cycle analysis which suggests a lower carbon footprint during production and end-of-life disposal.

Furthermore, nitrile rubber’s resistance to oil, chemicals, and abrasion not only extends its lifespan but also mitigates the waste generated from frequent replacements. Research from the Rubber Manufacturers Association indicates that using NBR in industrial applications can lead to a reduction in material waste by up to 30% compared to traditional rubber materials. Additionally, many manufacturers are now implementing recycling programs for nitrile products, enhancing their sustainability profile. This systemic improvement in the management of nitrile at its end-of-life stage bolsters its role in circular economy initiatives, promoting a greener future for industrial practices.

Related Posts

-

Best Nitrile Butadiene Rubber Performance Comparison Against Alternative Compounds

-

Top 7 Applications of Nitrile Butadiene Rubber in Automotive and Industrial Sectors with 30% Market Growth

-

What is the Science Behind Best Ultrasonic Welding Rubber

-

How to Select the Best Natural Gum Rubber for Your Sustainable Products

-

China's Resilience in Manufacturing Best Ultrasonic Welding Rubber Amidst US China Tariff Challenges

-

Exploring Sustainable Alternatives to Best Natural Gum Rubber for Global Buyers