How to Choose Nitrile Butadiene Rubber for Your Projects?

Choosing the right material for your project can be challenging. Nitrile Butadiene Rubber (NBR) stands out among various options. This versatile rubber is popular for its excellent resistance to oils and fuels. Many industries rely on it for seals, gaskets, and protective gear.

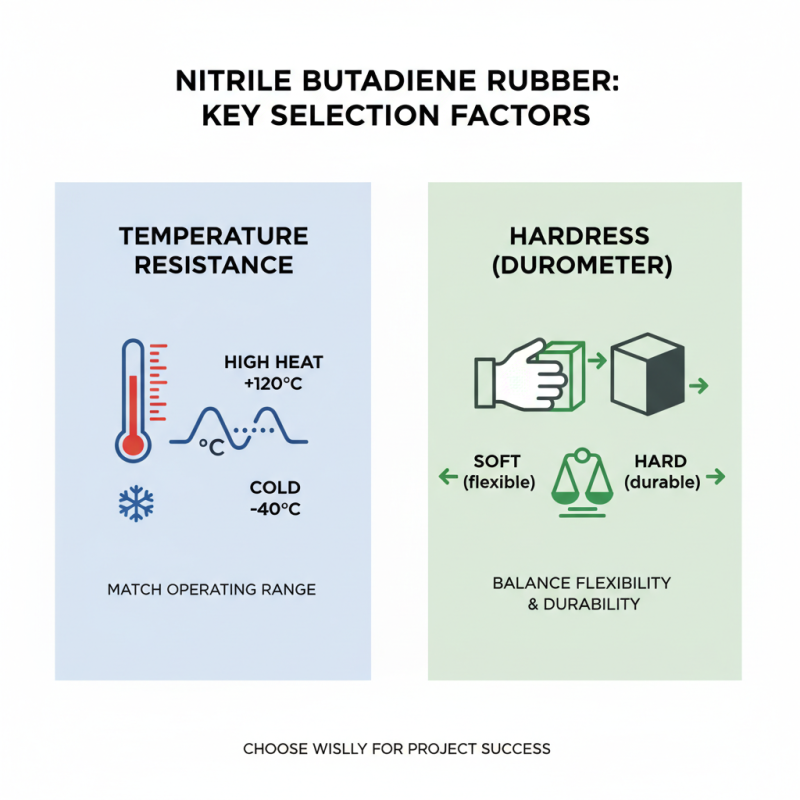

When selecting Nitrile Butadiene Rubber, consider its hardness, temperature range, and applications. Different NBR compounds exist, each tailored for specific uses. Some may not meet your needs. You must analyze your project requirements. Is durability your main concern? Or perhaps flexibility?

Understanding the characteristics of Nitrile Butadiene Rubber can help. However, mistakes can happen. Misjudging the right type can lead to project delays. Focus on research. Talk to suppliers about your specific needs. Your choice can determine project success or struggle. Always weigh the options carefully.

Factors to Consider When Choosing Nitrile Butadiene Rubber

When choosing nitrile butadiene rubber for your projects, consider the key factors that affect its performance. Temperature resistance is essential. Some applications need the material to work under high heat or cold. Identify the range you will encounter. Hardness, measured in durometer, influences flexibility. Softer materials may deform easier, while harder ones can be more durable. Find a balance that suits your needs.

Chemical resistance is another crucial aspect. Nitrile rubber withstands many oils and chemicals. However, it is not immune to all substances. For instance, exposure to certain solvents can degrade it. Always check compatibility charts. Other considerations include the thickness of the material. Thicker layers may provide better protection but can also limit flexibility. If your project requires intricate movements, think twice.

Think about processing methods. Some nitrile rubber can be more challenging to mold or cut. This may slow down production. Evaluate your manufacturing capabilities to avoid unexpected delays. Look out for the typical applications in your field. This can guide your decision. Choosing the right nitrile butadiene rubber involves careful thought. It's not a straightforward task. Each project has unique requirements. So, take your time and analyze all aspects.

Types of Nitrile Butadiene Rubber and Their Applications

Nitrile Butadiene Rubber (NBR) comes in various types, each suited for specific applications. One common type is standard-grade NBR, often used for automotive seals and gaskets. This rubber offers excellent resistance to oil and fuels. Its flexibility and durability make it ideal for parts that face varying temperatures.

On the other hand, high-performance NBR is formulated for harsher conditions. It is suitable for applications like industrial hoses and aggressive chemical environments. This type provides superior wear resistance but may require careful handling during manufacturing. It's important to assess whether the added cost justifies its benefits.

Another variation, hydrogenated NBR, features enhanced thermal stability. This type is beneficial for products exposed to higher temperatures. However, its processing can be more challenging, potentially leading to wasted materials or time. Each type offers unique advantages yet carries its own set of challenges. It's crucial to reflect on the project requirements before selection.

Evaluating Physical Properties for Specific Project Needs

When choosing nitrile butadiene rubber (NBR) for your project, evaluating its physical properties is crucial. Start by considering the tensile strength, which indicates how much force the material can withstand. NBR can exhibit varying strengths depending on its formulation. Some grades can resist up to 50 MPa, while others fall short. Check the specifications carefully to match your project requirements.

Next, focus on the hardness scale, typically measured in Shore A. Depending on your application, you might need a harder or softer material. Softer NBR has better flexibility, while harder grades resist wear and tear. A common mistake is ignoring how these properties affect performance in real-world conditions. For instance, a softer rubber might wear out quickly in high-friction environments.

Moreover, consider chemical resistance. NBR is known for its resistance to oils and fuels, but it might not hold up against certain chemicals. Testing in your specific environment before full-scale production can save you from unexpected failures. It's tempting to assume all NBR is the same, but small differences in the formulation can lead to big discrepancies in performance. Always reflect on how each property aligns with your project's goals.

Cost Analysis: Budgeting for Nitrile Butadiene Rubber Options

When budgeting for nitrile butadiene rubber (NBR), it’s essential to consider several factors. The cost of NBR can vary significantly based on grade, supplier, and quantity. Understand that higher quality usually comes at a premium. A small quantity may seem cheaper initially but can lead to higher per-unit costs.

Tips: Always compare prices from multiple suppliers. Even slight variations can impact your overall budget. Consider the long-term benefits of investing in quality; durability may save you replacement costs down the line.

Another factor affecting your budget is material properties. Different projects may require specific NBR characteristics, such as temperature resistance or oil compatibility. Not every type may fit your needs as intended. Assess what you really need versus what is available.

Tips: Think about future projects when selecting materials. Choosing a versatile option can pay off. Don't forget to account for shipping costs, which can impact your final expense. Always review your budget choices critically; reconsider the most important functionalities.

How to Choose Nitrile Butadiene Rubber for Your Projects? - Cost Analysis: Budgeting for Nitrile Butadiene Rubber Options

| Application | Thickness (mm) | Price per Meter ($) | Durability (Years) | Temperature Range (°C) |

|---|---|---|---|---|

| Automotive Seals | 3 | 5.50 | 10 | -40 to 120 |

| Industrial Hoses | 5 | 8.00 | 8 | -20 to 100 |

| Gaskets | 2 | 4.00 | 15 | -30 to 150 |

| O-Rings | 1 | 2.50 | 12 | -10 to 90 |

| Grip Pads | 4 | 6.00 | 5 | -20 to 80 |

Sourcing and Suppliers: Finding Quality Nitrile Butadiene Rubber

Finding quality nitrile butadiene rubber (NBR) is crucial for various projects. Start by identifying your specific needs. Consider the application and required specifications. Different types of NBR are available. They vary in hardness, resistance, and other properties. Knowing what you need helps guide your search.

Next, research potential suppliers. Look for companies that specialize in NBR. Read reviews and check their reputation. Not all suppliers meet quality standards. Contact multiple suppliers to compare their offerings. Don’t hesitate to ask questions about their materials. Sometimes their responses can reveal a lot about their expertise.

Engage with your chosen suppliers. Request samples to assess the quality. A physical inspection helps you make better decisions. Keep an open mind during the process. Some suppliers may provide unexpected options. Reflect on your choices and remain flexible in your approach. Finding the right NBR supplier can significantly impact your project’s success.

Quality Comparison of Nitrile Butadiene Rubber Supplies

Related Posts

-

7 Essential Tips for Optimizing Injection Molding Nitrile Rubber Production

-

Top 7 Applications of Nitrile Butadiene Rubber in Automotive and Industrial Sectors with 30% Market Growth

-

Why Nitrile Butadiene Rubber is the Preferred Choice for Industrial Applications

-

Challenges Faced in Waterjet Cutting Rubber Processes and Their Impact on Production Efficiency

-

Exploring Innovative Alternatives to Polyisoprene Rubber in Modern Manufacturing

-

How to Source the Best Vulcanizing Rubber for Your Production Needs