10 Best Laser Cutting Rubber Techniques for Precision and Efficiency

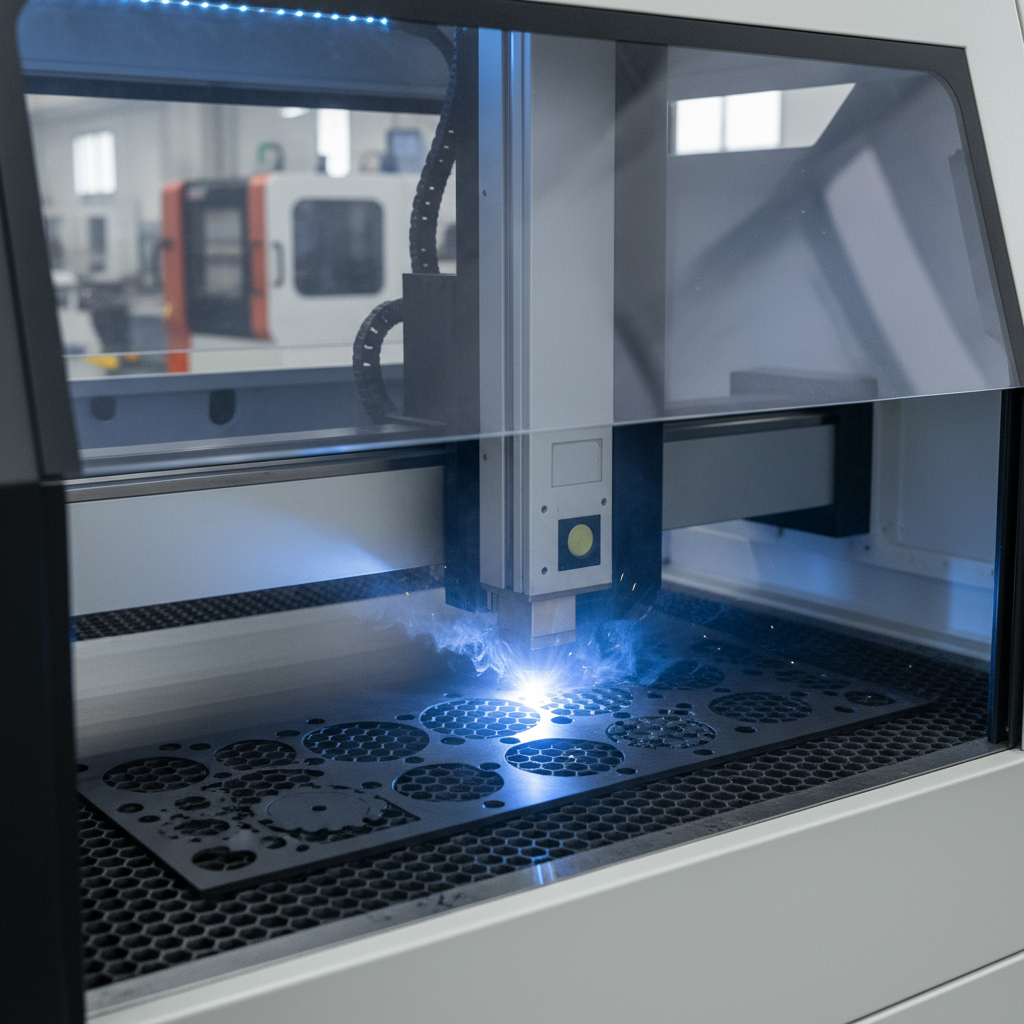

In the ever-evolving world of manufacturing and design, the art of laser cutting rubber has emerged as a pivotal technique for achieving unparalleled precision and efficiency. As industry experts underline the significance of this technology, John Anderson, a leading figure in the laser cutting field, emphasizes that “the future of rubber fabrication lies in our ability to harness laser technology for detailed and intricate designs.” This statement encapsulates the transformative potential of laser cutting rubber, making it a preferred choice for designers and manufacturers alike.

With the capability to create complex shapes and patterns with minimal material waste, laser cutting rubber not only enhances productivity but also elevates the quality of the final products. As we delve into the ten best techniques for laser cutting rubber, we will explore how these methods can optimize workflows and ensure consistent results. From selecting the right laser parameters to understanding the nuances of different rubber materials, mastering these techniques is imperative for those looking to stay ahead in this competitive landscape. The insights shared in this article aim to equip professionals with the knowledge to leverage laser cutting rubber effectively, setting a new standard in the industry.

Top 10 Laser Cutting Techniques for Optimal Rubber Precision and Effectiveness

Laser cutting has revolutionized the way rubber components are designed and manufactured, offering unparalleled precision and efficiency. When exploring the top techniques for optimal rubber cutting, the focus remains on the adaptability of laser technology in meeting diverse requirements. Techniques such as raster engraving allow for intricate designs while maintaining clean edges, making it ideal for detailed graphic applications. Furthermore, vector cutting ensures that rubber sheets are sliced with remarkable accuracy, reducing waste and enhancing overall productivity.

Another pivotal technique is the use of varying laser power settings, which can be adjusted to suit different types of rubber. This customization enables manufacturers to cut through thick and thin materials alike, ensuring that each product meets specific design criteria without compromising quality. Additionally, implementing assist gas during the cutting process can significantly enhance the surface finish, minimizing charred edges and optimizing the final product's performance. By incorporating these advanced laser cutting techniques, businesses can achieve optimal rubber precision and effectiveness in their operations, driving innovation and elevating results.

How to Choose the Right Laser Type for Rubber Cutting Applications

When it comes to laser cutting rubber, selecting the right type of laser is crucial for achieving optimal precision and efficiency. The most commonly used laser types for rubber cutting include CO2 lasers, fiber lasers, and diode lasers. CO2 lasers are highly effective for cutting a wide variety of rubber materials, delivering clean edges and intricate designs. Fiber lasers, while less common for rubber, can be advantageous for specific applications requiring high speed and precision. Diode lasers may be suitable for thinner rubber materials and can offer cost-effective solutions for smaller projects.

**Tips:** Always consider the thickness and type of rubber you plan to cut. For thicker materials, a CO2 laser may provide the necessary power and depth, whereas a fiber laser can handle intricate details efficiently. Additionally, ensure your laser system is equipped with the appropriate settings for rubber, such as adjusting the speed and frequency to reduce the risk of burning or melting the edges.

Furthermore, it’s essential to maintain a clean working environment. Rubber cutting can produce debris and fumes that affect both the quality of the cut and the longevity of your equipment. Regularly cleaning the lens, as well as the cutting area, will enhance performance and ensure precise results with each project.

Top 10 Laser Cutting Techniques for Rubber

Essential Settings for Laser Cutting Rubber: Speed, Power, and Frequency

When it comes to laser cutting rubber, achieving precision and efficiency hinges on the essential settings of speed, power, and frequency. The right balance of these parameters is critical for producing clean cuts and maintaining the integrity of the material. High-speed settings can enhance productivity, but if the power is too high, it may lead to burning or unwanted marks on the rubber. Conversely, low power settings might not cut through the material effectively, resulting in jagged edges and a longer processing time.

To optimize the laser cutting process, it’s vital to understand the specific requirements of the rubber type being used. Different rubber compositions may require adjustments in frequency to improve cutting performance. For instance, increasing the frequency can produce finer cuts for detailed designs, while lower frequencies might be suitable for thicker materials. By fine-tuning these settings, users can achieve high-quality results, ensuring both efficiency and precision in their laser cutting projects.

Finishing Techniques Post-Laser Cutting: Achieving the Perfect Edge

When it comes to laser cutting rubber, achieving the perfect edge is crucial for both aesthetics and functionality. The intense heat generated during the cutting process can sometimes result in rough or burnt edges. To counteract this, several finishing techniques can be employed post-laser cutting. Firstly, sanding the edges with fine-grit sandpaper can smooth out any imperfections and create a polished finish. This step not only enhances the visual appeal but also improves the tactile quality of the rubber, making it more pleasant to handle.

Another effective method for refining edges is the use of chemical treatments. Applying a solvent or edge sealer can help in melting the micro-frayed edges caused by the laser, resulting in a smoother and more uniform appearance. Additionally, heat treatment using a heat gun can further refine the edges by gently melting the surface of the rubber without damaging its structure. By combining these finishing techniques, manufacturers can significantly enhance the quality of their laser-cut rubber products, ensuring that they meet precision and efficiency standards while delivering a professional finish.

10 Best Laser Cutting Rubber Techniques for Precision and Efficiency - Finishing Techniques Post-Laser Cutting: Achieving the Perfect Edge

| Technique | Description | Efficiency Rating | Precision Level | Post-Cutting Finishing |

|---|---|---|---|---|

| High Speed Cutting | Utilizing high-speed laser settings to enhance cutting efficiency. | 90% | High | Minimal edge finishing required |

| Low Power Cutting | Lower power settings for delicate materials to avoid burning. | 85% | Medium | Requires sanding for smooth edges |

| Vector Cutting | Precision cutting along defined paths for intricate designs. | 92% | Very High | Requires minimal post-processing |

| Raster Cutting | Engraving designs using raster techniques for detailed work. | 80% | High | May require additional finishing |

| Air Assist Cutting | Using compressed air to clear debris and improve edge quality. | 87% | Medium | Reduced burning, less finishing needed |

| Cooling Techniques | Using cooling agents to minimize heat and maintain material quality. | 88% | High | Decreases post-cutting adjustments |

| Masking Techniques | Applying masking material to reduce residue and protect edges. | 95% | Very High | Offers a clean finish with no additional work |

| Slow Cutting for Thick Rubber | Adjusting speed for thicker materials to ensure clean cuts. | 84% | High | Limited edge curling, some sanding may be needed |

| Optimization of Settings | Fine-tuning laser settings for various rubber types for ideal results. | 93% | Very High | Minimal adjustments post-cutting |

Safety Best Practices for Advanced Laser Rubber Cutting Processes

When it comes to advanced laser cutting processes for rubber, safety is of paramount importance. According to a report by the Occupational Safety and Health Administration (OSHA), improper laser cutting procedures can lead to serious workplace hazards, including exposure to harmful fumes and burns. Therefore, implementing safety best practices is essential for ensuring a secure working environment. Operators should always wear appropriate personal protective equipment (PPE), including goggles, gloves, and respirators, to minimize exposure to laser hazards and potential toxic smoke released during the cutting process.

Another critical safety consideration involves maintaining proper ventilation in the workspace. The American Conference of Governmental and Industrial Hygienists (ACGIH) emphasizes that effective ventilation can reduce exposure to airborne contaminants significantly, minimizing health risks for both operators and nearby personnel. Additionally, regular maintenance of laser cutting equipment is crucial to prevent malfunctions that could lead to accidents. Comprehensive training programs that focus on proper operational techniques and emergency protocols can further enhance safety standards in advanced laser rubber cutting processes, ultimately increasing productivity while safeguarding employees.

Related Posts

-

Exploring Innovative Alternatives to Laser Cutting Rubber for Global Suppliers

-

Innovative Solutions for Molding Rubber Applications in Global Manufacturing

-

What is the Science Behind Best Ultrasonic Welding Rubber

-

Future Trends in Best Polybutadiene Rubber Market for 2025 and Beyond

-

Challenges Faced in Waterjet Cutting Rubber Processes and Their Impact on Production Efficiency

-

5 Key Reasons to Choose Brominated Butyl Rubber for Your Next Project