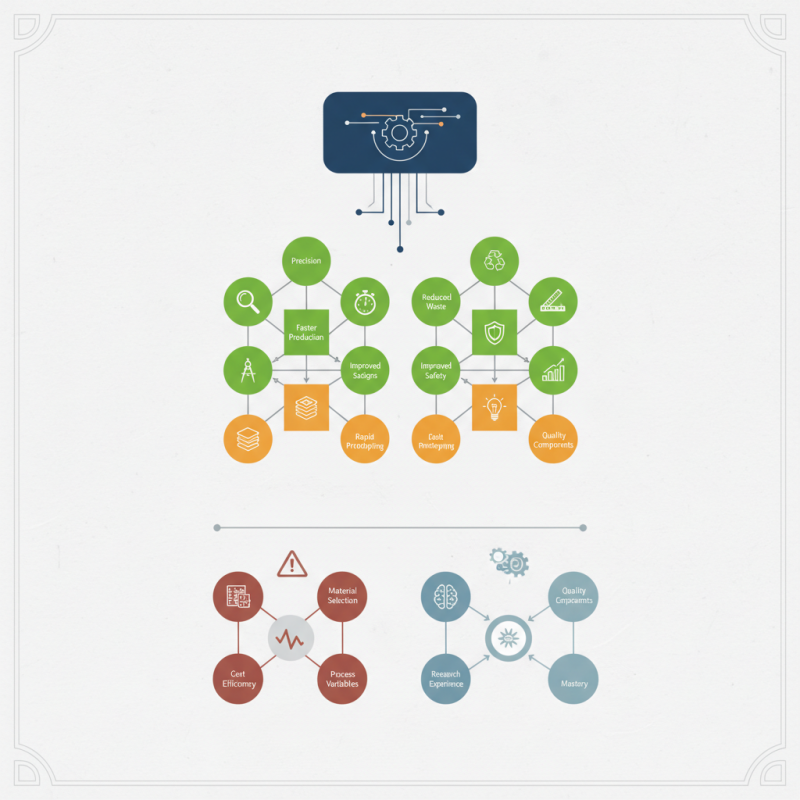

Top 10 Benefits of Laser Cutting Rubber for Your Projects?

Laser cutting rubber has become an essential technique in various industries. According to a recent report by the International Rubber Association, the demand for precision rubber components is steadily increasing. This trend highlights the importance of efficient manufacturing processes, such as laser cutting rubber.

Expert Dr. John Parker, a leading figure in the field, states, “Laser cutting rubber allows for intricate designs and faster production times.” This technology offers unmatched accuracy, enabling manufacturers to create detailed prototypes and components quickly. However, there are challenges. For instance, selecting the right type of rubber can affect the quality of the cut.

The benefits of laser cutting rubber are vast, ranging from reduced waste to improved safety. Yet, not all projects achieve optimal results. Understanding the limitations and variables involved in the process is crucial. Thus, research and experience play vital roles in mastering the art of laser cutting rubber.

Advantages of Laser Cutting Rubber for Precise Material Shaping

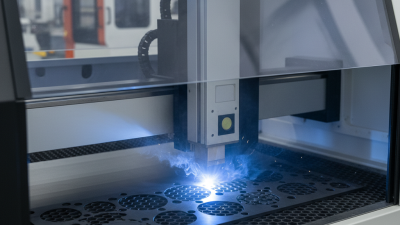

Laser cutting rubber boasts several key advantages that enhance material shaping in various projects. Precision is one of the most significant benefits. According to a report by the Fabricators & Manufacturers Association, laser cutting technology can achieve tolerances of ±0.1 mm. This level of accuracy is crucial when creating detailed prototypes or intricate designs. The focused laser beam melts the rubber instead of tearing it, resulting in clean edges and smooth finishes.

Another noteworthy aspect is the reduction in material waste. A study published by the Journal of Manufacturing Processes indicates that laser cutting minimizes waste by up to 30% compared to traditional cutting methods. This efficiency not only saves costs but also supports environmentally friendly practices. However, achieving precise cuts consistently can be challenging. Variations in rubber thickness or hardness might lead to uneven results. This requires operators to carefully calibrate their machinery to maximize efficiency while maintaining quality.

Additionally, laser cutting allows for complex shapes that are otherwise difficult to achieve. Intricate designs, fine patterns, and small cutouts can be executed swiftly. Yet, the process isn't flawless. There may be drawbacks, like heat affecting certain rubber qualities. Understanding these limitations is essential for optimizing results. Proper preparation and adjustment can mitigate these issues, ensuring the desired outcome in every project.

Enhanced Efficiency: Speed and Accuracy in Production Processes

Laser cutting rubber has transformed production processes in various industries. Enhanced efficiency is evident in speed and accuracy. Projects can move from design to completion quickly. The technology allows for intricate designs that manual cutting often fails to achieve. This precision reduces material waste and enhances overall production quality.

Speed is another key advantage. Traditional methods can be slow and labor-intensive. Laser cutting drastically cuts down production time. Workers can focus on other tasks while machines do the cutting. However, there are challenges too. Some may struggle with machine calibration or software adjustments, leading to delays. It's essential to invest time in training to maximize benefits.

Accuracy goes hand in hand with speed. Complex designs are executed flawlessly, which leads to better-fitting parts. Yet, not every project is suited for laser cutting. Thicker rubber may present limitations. Some users find that the edges may not be as clean as expected. It’s vital to assess material types and thicknesses before committing. Through careful consideration, efficiency can be greatly enhanced while ensuring top-notch results.

Versatility of Laser Cutting: Adapting to Various Rubber Types

Laser cutting has transformed how we approach various materials, especially rubber. Its versatility is significant. Different rubber types can be precisely cut to meet specific project needs. For soft rubber, laser cutting delivers clean edges without fraying. This results in parts that fit together perfectly.

Moreover, thin and thick rubber sheets can be handled with efficiency. Thick materials pose challenges, yet laser technology can adjust settings for depth and speed. This adaptability allows for intricate designs that would be difficult with traditional methods. However, sometimes the settings need tweaking to avoid overburning or melting, which can happen. Testing a sample piece beforehand becomes crucial.

Customization is another key benefit. Unique shapes, logos, or patterns can be created on demand. This opens doors for personalized projects, enhancing creativity. Yet, one might find that not all rubber types yield the same sharpness or detail. Reflecting on such variations can improve future designs. Each project provides learning opportunities, ensuring refinement in the laser cutting process.

Reduced Material Waste: Cost-Effective Solutions for Projects

Laser cutting rubber offers significant advantages, particularly in reducing material waste. Traditional cutting methods often waste up to 20% of the material used. In contrast, laser cutting provides precision and minimizes off-cuts. Reports indicate that companies adopting laser technology have seen waste reduction by nearly 30%. This efficiency translates directly into cost savings.

Moreover, laser cutting allows for intricate designs that traditional methods struggle to achieve. Custom shapes can be made without compromising material integrity. Each project can be tailored specifically to client needs, reducing excess materials. This precision is especially vital in industries like automotive and manufacturing, where every ounce of material counts.

However, there are challenges. The initial investment for laser cutting technology can be high. Some businesses may find it difficult to justify the upfront costs. Ongoing maintenance and training also present hurdles. Balancing these factors is crucial for maximizing benefits. Transitioning can require time and adjustment. Businesses must weigh the long-term savings against initial expenditures.

Improved Design Flexibility: Breaking Traditional Manufacturing Constraints

Laser cutting technology brings extraordinary design flexibility to rubber projects. Traditional manufacturing often constrains creativity. However, laser cutting frees designers from these limitations. Complex shapes and intricate details come to life with precision. The ability to customize cuts allows for innovative approaches in product creation. Patterns that were once difficult or impossible to achieve can now be easily crafted.

This improved flexibility can, however, pose a challenge. Designers must adapt to new possibilities and rethink their approaches. Some may feel overwhelmed by the options available. Rapid prototyping is now easier, but it requires thoughtful planning. Each design choice impacts the final product's functionality and appearance. Balancing creativity with practicality presents a unique dilemma.

Moreover, the accuracy of laser cutting means that even small mistakes can be magnified. Designers should be meticulous in their approach. Ensuring that every measurement is precise is crucial. The process demands both technical skill and artistic vision. Ultimately, while laser cutting enhances design possibilities, it also invites deeper reflection on the balance between innovation and execution. Each project becomes a learning experience, rich with opportunities for growth.

Top 10 Benefits of Laser Cutting Rubber for Your Projects

Related Posts

-

Exploring Innovative Alternatives to Laser Cutting Rubber for Global Suppliers

-

Exploring the Impact of Laser Cutting Rubber Technology at the 137th Canton Fair in Guangzhou

-

10 Best Laser Cutting Rubber Techniques for Precision and Efficiency

-

Best Laser Cutting Silicone Rubber Techniques for Precision?

-

Best Nitrile Butadiene Rubber Performance Comparison Against Alternative Compounds

-

Advantages of Utilizing Rubber Processing Techniques for Global Trade